Super product, specially designed for all types of typical applications.

"Dual treatment water conditioner, the ultimate in scale control" MagCat is a combination of magnetic and catalytic treatment systems into a single compact stainless steel housing providing the most complete reaction available for calcium carbonate treatment. It is the cost effective answer to a problem which costs industry millions of rupees each year.

MagCat Range

MagCat Industrial

Designed for industrial and waste water including water that has contaminations such as oil. You can see from the picture below the layout of MagCat industrial

MagCat+

In some waters we found that Scaletron was not working so well because the water was very soft, but still having scaling problems. So we designed a product with more power where the water was treated. The idea was to have a magnetic chamber in the same place as the Scaletron alloy, we made some proto types and trailed in areas where we had the problems and it has been working very well. May be 5% of all waters are not suitable for Scaletron because the pH is too low or hardness is too low so in the past we say no, but now we have a solution

The latest development from Fluid Dynamics - Environment friendly water treatment where traditional methods have failed.

Its nearly 40 years since Fluid Dynamics developed its first non chemical water treatment product to combat calcium carbonate scaling. Whilst the market was slow to embrace the idea that a simple principle could prevent what was a complex and costly problem today it's a different story.

Environmental pressures and the drive to reduce cost has seen some of the largest companies across the world install equipment manufactured by Fluid Dynamics,establishing us as the leaders in industrial non-chemical water treatment. Ford Motor Co.Unilever, Kellogg's & Kimberley Clark are just a small selection of the companies who we have provided equipment and continue to work with reducing cost and their chemical consumption.

Why does MagCat excel

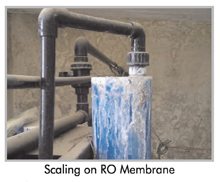

MagCat is the result of years of development coupled with decades of experience in treating industrial water systems. developed using a combination of Fluid Dynamics established catalytic and magnetic technologies it is capable of treating a vast array of different types of water that scale aggressively such as water with high TDS levels or even seawater.

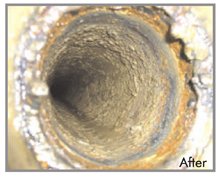

MagCat has successfully eliminated or substantially reduced chemical & CO2 dosing whilst still extending or eliminating cleaning procedures in process equipment or pipelines.

MagCat treats water without polluting or sacrificing any elements into the stream, making it totally environment friendly, eliminating the need for treat- ing water to remove chemicals before it is rejected into main water ways.

Water conditioning

In our experience the most effective types of water conditioners are invasive, i.e they are within the pipe and not external, and create turbulence as water is treated.

There are many different types of conditioner, Fluid Dynamics manufactures ‘’Catalytic’’ and Catalytic + Magnetic as a dual treatment system.

Stand alone magnetic systems (i.e conditioners that rely solely on a magnetic, electronic or electromagnetic field) that have no turbulence seem to have a limited range of treatment in terms of the spectrum of water quality they can treat as well as the level of treatment ‘’suitable’’ water receives, this is why Fluid Dynamics do not manufacture a Magnetic only water conditioner.

Magnetic water conditioning

The aim of water conditioners is to precipitate the bulk of water hardness as microscope insoluble calcium carbonate crystals that cannot form hard scale, the calcium carbonate crystal created by stand alone magnetic treatment shows the bond between calcium and carbonate is not strong and reverts back to solution quite quickly. Water quality also plays an important role as the water passing through the conditioner is necessary to create the electrical reaction conditioners are trying to achieve. Magnetic conditioners for instance use faradays principle i.e passing a conductive fluid (water) through a magnetic gap (magnetic conditioner) a current will be generated. Therefore how conductive the water is plays a role in how effective conditioners will be. Some conditioners (typically non-invasive conditioners that create no turbulence) have a much more limited spectrum of water quality that they can treat, If water is too soft (i.e not conductive enough) the electrical charge generated is insufficient, likewise if water is too hard then because of the weaker mechanism they employ not enough precipitation takes place during treatment to prevent hard scale from forming downstream.

/>

/>

MagCat Range

MagCat Industrial

Designed for industrial and waste water including water that has contaminations such as oil. You can see from the picture below the layout of MagCat industrial.

MagCat Industrial Data Sheet

| MAGCAT NOMINAL DIAMETER | MAX FLOW M3/HR | UNIT LENGTH MILLIMETERS | MAX PRESSURE BAR | WEIGHT KGS |

|---|---|---|---|---|

| DN25 | 6.2 | 550 | 16 | 2.5 |

| DN32 | 10.1 | 750 | 16 | 5 |

| DN40 | 15.9 | 800 | 16 | 6 |

| DN50 | 30.7 | 800 | 16 | 9 |

| DN65 | 51 | 1000 | 16 | 11 |

| DN80 | 74 | 1000 | 16 | 30 |

| DN100 | 110 | 1000 | 16 | 46 |

| DN125 | 160 | 1000 | 16 | 65 |

| DN150 | 255 | 1000 | 16 | 80 |

| DN200 | 440 | 1000 | 16 | 132 |

| DN250 | 650 | 1000 | 16 | 187 |

| DN300 | 750 | 1000 | 16 | 297 |

| DN350 | 440 | 1000 | 16 | 375 |

MagCat Plus

This is a brand new development. In some waters we found that Scaletron was not working so well because the water was very soft, but still having scaling problems. So we designed a product with more power where the water was treated. The idea was to have a magnetic chamber in the same place as the Scaletron alloy, we made some prototypes and trailed in areas where we had the problems and it has been working very well. Maybe 5% of all waters are not suitable for Scaletron because the pH is too low or hardness is too low so in the past we say no, but now we have a solution.

MagCat Plus Data Sheet

| MAGCAT NOMINAL DIAMETER | Max Flow m3/hr | Length mm | Weight kg | Connection Type |

|---|---|---|---|---|

| dn15 (15mm) | 1.6 | 400 | 2.5 | 1/2"BSP |

| dn20 (22mm) | 3.6 | 400 | 4.9 | 3/4" BSP |

| dn25 (28mm) | 5.2 | 450 | 5.5 | 1"BSP |

| dn32 (35mm) | 8.2 | 550 | 6.5 | 1 1/4"BSP |

| dn40(42mm) | 13.5 | 550 | 8.0 | 1 1/2"BSP |

| dn50 (54mm) | 20 | 550 | 10 | 2" BSP |

| dn65 | 29 | 800 | 18 | 2.5" Flange |

| dn80 | 54 | 850 | 30 | 3" Flange |

| dn100 | 80 | 850 | 46 | 4" Flange |